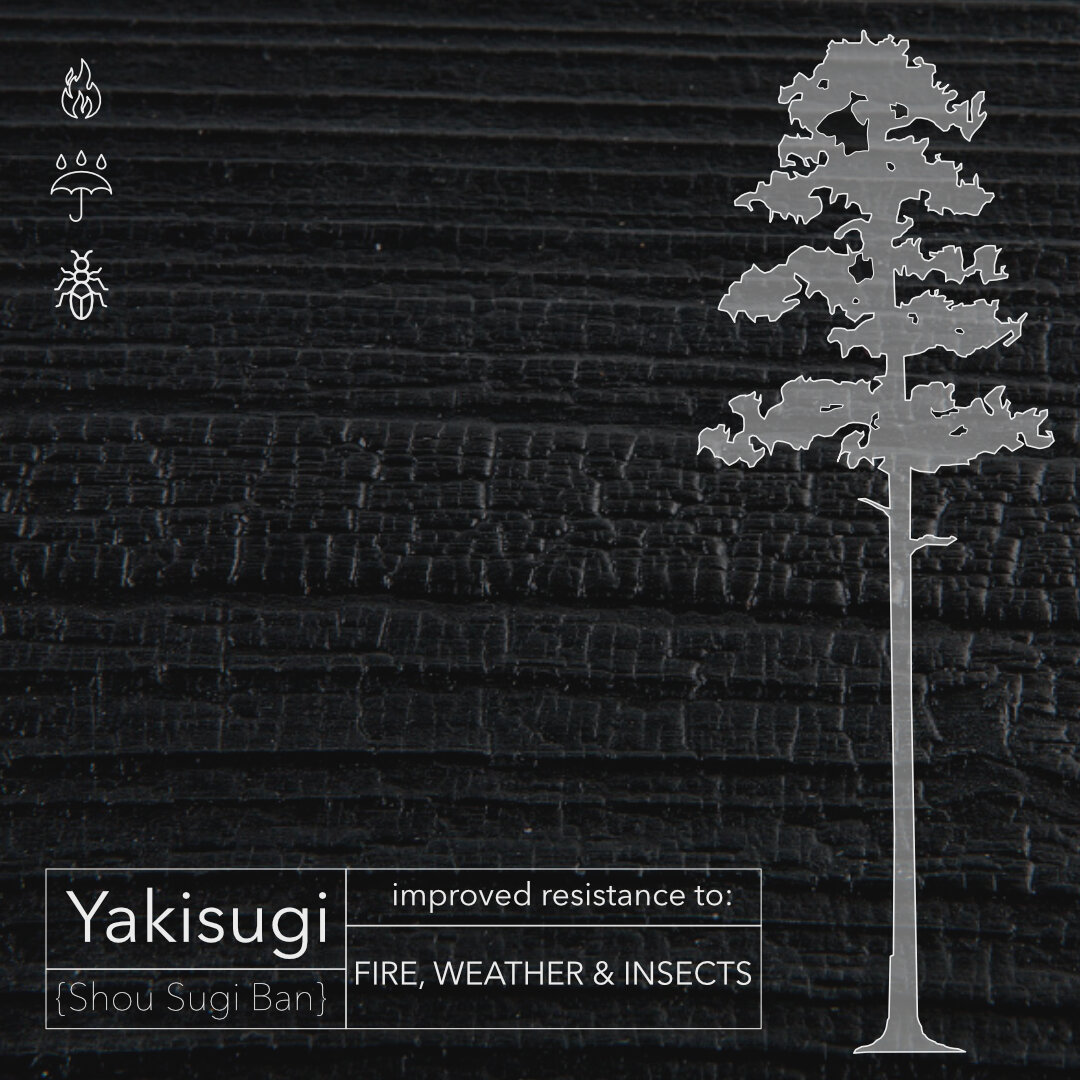

Yakisugi

Fire icon by Aisyah from the Noun Project; Bug icon by Eleanor Bell from the Noun Project; Raining icon by Adnen Kadri from the Noun Project

A few weeks ago we posted some pics and videos of us heat treating (aka burning) a chunk of lumber for an awesome custom mantlepiece. This sort of technique helps prevent decay, insect damage, improves fire resistance stabilizes the wood dimensionally and just looks cool. We called it "shou sugi ban". And as it turns out, this is a bit of a misnomer. First of all, "shou sugi ban" is a western misinterpretation of the Japanese term "yakisugi". They share the same Japanese kanji symbols, but have totally different pronunciations. It is an interesting linguistic story if you are into that sort of thing, but not something I am so interested in recounting here. Just know that in the west, "shou sugi ban" refers to the same thing as "yakisugi", but in Japan only "yakisugi" is used.

To be clear, what we did was borrow the ideas and principles of yakisugi and apply it to a particular situation. This does not make what we did yakisugi. Yakisugi is a product, not a technique. And this product is very specific to using Japanese Cypress (Chamaecyparis obtusa) in either plain sawn or quarter sawn planks. These planks are then used for siding (vertical or horizontal), soffit work, exposed roof decking/shingles, walls and ceilings (interior or exterior). If it is not this then it is not yakisugi. The Japanese Cypress is a species that that is perfect for this kind of heat treatment; it grows tall and straight with tight growth rings, it is naturally insect, rot, and mildew resistant, and the soot created during burning is much more substantial and tougher than what is created on other types of wood. All of this coupled with the heat treatment makes for an incredibly durable, natural cladding. Examples are common of this being used with very little maintenance for 80 or 100 years. Depending on desires yakisugi can be regularly oiled to lengthen its life or just left up with no maintenance and replaced. Either way, you are looking at multiple decades of use.

So now that we are convinced that yakisugi is the best thing before sliced bread, let's get technical. To produce yakisugi properly is time intensive and requires practice and development of judgement. The traditional technique is to bind 3 planks together and start a fire in the middle while they are on their side. Once the flames take hold the planks are stood up and allowed to burn and char. For a quality product the char must be 3mm thick. You can expect this to take something like 7 to 10 minutes. Another common technique, that in some ways is easier, is to use a large gas torch to burn the surface. Once the wood is charred sufficiently, the planks are separated and the burning stopped by dowsing it with water. Care must be taken now, because not only is the wood exceptionally hot, but it can easily be warped in this state. Once it has cooled it will be quite stable and able to resist extreme weather and temperatures. After the wood has cooled sufficiently it is cleaned with a brush to remove any loose soot or char. This initial cleaning is done with a soft broom to maintain the structural integrity of the char and leave that distinctive "alligator skin" texture. If it is oiled at this point it is called "suyaki", or "original char". However, you can brush it again with a wire brush and remove the softest char, but leaving the black base layer. This is called "gendai" or "brushed. Finally, if you really want to go at it you can brush it again, taking it back down to wood leaving only the blackened growth rings. This is called "pika=pika" or "twice-brushed". All three types of yakisugi are distinctly beautiful but it should be noted that the more soot and char that is removed the less weather protection and longevity the wood would have.

So there you have it, a quick intro to yakisugi. Yakisugi is getting a lot more well deserved attention worldwide by the design community because of its sustainability and dramatic aesthetic, but in Japan it is simply an elegant utilitarian solution. Hopefully this interest will generate thoughtful integration and not merely be relegated to an aesthetic treatment. Heating treating wood is a ancient and universal human technology and has taken a variety of forms throughout history and around the globe. Though maybe not as beautiful or romantic as yakisugi, there are a number of promising technologically advanced heat treatment methods being developed. Allowing for a more natural and sustainable way to enhance the lumber we use.

And just so we are clear, we are a custom fabrication studio that is passionate about design, the creative process and materials. We do not produce yakisugi, but we love everything that it is so we felt like it is worth sharing.

"By weight wood is mostly structural lignin, with the balance hemi-cellulose carbohydrates that are food for fungi and insects. Heat treatment of yakisugi burns off the cellulose, minimizing rot and infestation. The heat treatment also case hardens the planks, and in combination with air drying, reduces dimensional movement in severe weather exposure. The soot layer increases the temperature threshold needed for combustion, dramatically reducing flame spread. The hydrophobic soot layer and hardened surface slow down weathering, making it maintenance-optional." - Nakamoto Forestry

Relevant Links:

nakamotoforestry.com

shousugiban.com

shizenstyle.com